To place an order for this product or other items, please contact us via email. Kindly include your company name, order quantity, and the desired product in your message, so we can assist you accordingly.

Brief Introduction:

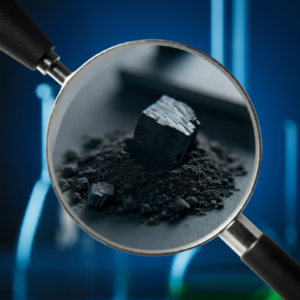

Black Carbon is a fine particulate material produced by the incomplete combustion of carbon-containing substances such as oil, gas, coal, and biomass. Widely used in the production of tires, paints, inks, and as a reinforcing agent, black carbon enhances the mechanical properties of final products due to its specific physical and chemical properties.

Product Category:

Black carbon falls under the categories of inorganic chemical compounds and industrial reinforcements.

Applications:

Scientific Properties:

Consumption Barriers:

Standards:

Produced and quality-controlled according to international standards such as ASTM D1765 and ISO 11219.

Storage Conditions:

Should be stored in dry, cool locations away from combustible materials and heat sources. Moisture exposure should be avoided to maintain product integrity.

Best Manufacturers:

Major Consumers: